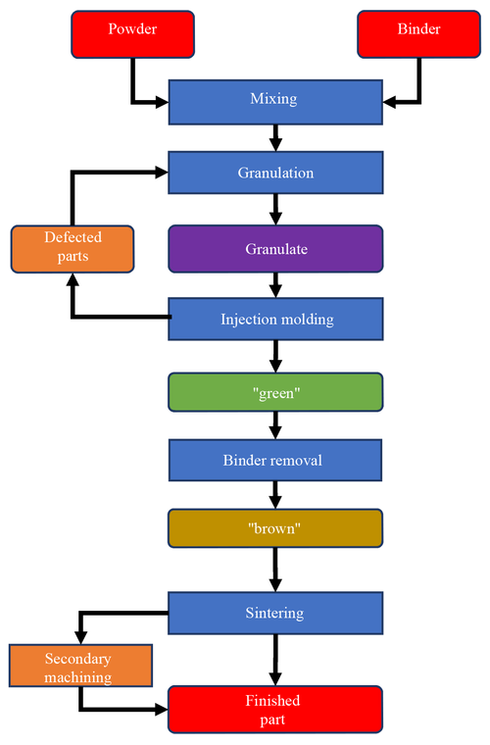

MIM process flow chart

The production of “green” objects by injection molding of a metal powder in the polymer matrix has been developed in the 70s and initially used in the ceramics sector to be then adapted, ten years later, to the metal powders. In principle, the process is pretty simple (see figure).

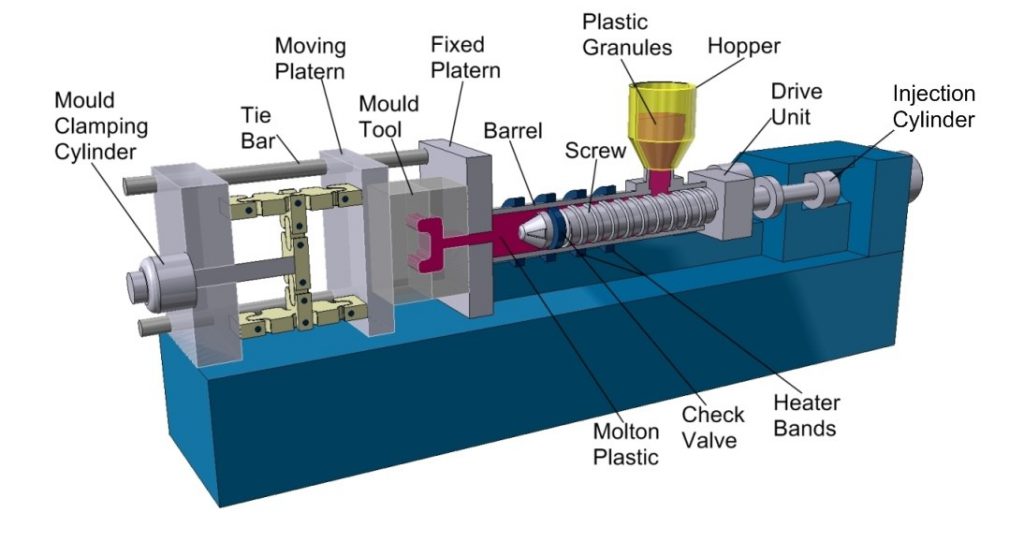

The metal powder is thoroughly mixed with a thermoplastic resin and processed with a kneading extruder or a roller to obtain the feed material plasticized, usually in granular form (feedstock). This material is injected into a heated mold in a similar way to what is done for the molding of plastics; initially, in fact, they used the same injection machines. The “green” article is extracted from the mold, the binder removed, i.e. the resin, and the part is sintered. Density of over 95 percent are obtainable to date, giving the surface properties comparable to those of the material produced according to traditional metallurgy and with a very high dimensional accuracy.

It can be inferred that the process is significantly more expensive than the traditional one. The rationale for its use is that it is possible to produce parts with highly complex geometries otherwise impossible to achieve. Given their complexity, with the production of traditional subtractive manufacturing systems would be very expensive.

The MIM process requires a number of expedients. One of the secrets to succeed – despite the large body of existing literature there are still (and not a few) trade secrets – is the formulation of the binder (binder). Among the many attributes necessary, it must be able to wet the granules of powder and form a uniform mass, be easy to remove and not cause deformation, or worse, breakage of the article. Since the first proprietary process was launched, a large applied research activity was conducted. Nowadays a large number of different formulations are available (some patents are expiring).

Also for the powder there are some tricks to be taken into account. To obtain an easily injectable raw material and a uniform load of powder, the powder should be particularly fine and with high sphericity. The carbonyl iron and Nickel alloys powders are required with a granulometry comprised between 2 and 10 microns. Regarding stainless steel powders, today’s dominant material in the MIM productions, they are generally obtained by gas-atomizing and must have a particle size of less than 40 microns. The amount of the binder reaches 50 percent by volume. Use fine powders has a further advantage: it sinters more rapidly thanks to the large contact surface (respect to volume).

The removal of the binder is another critical operation. The initial method was the heating of the parts with attention to cause decomposition of the binder or its evaporation. It is a slow process which, in function of the article section to the maximum thickness, could take from a few hours to a few days. Therefore other procedures were developed for removal (debinding) able to reduce the time required. One of these is the catalytic decomposition, a patented process, in which a polyacetal binder (acetal resin) is removed in gaseous environment acid (nitric acid or oxalic acid) at a temperature of about 120°C, then burning the reaction products in a natural gas flame. Also techniques based on the use of solvents were developed, where the binder includes a constituent which can be dissolved in a liquid at room temperature so as to form a network of interconnected porosity. For obvious environmental reasons water-soluble constituents are preferred rather than organic.

The relatively long time required for removal of the binder and its dependence on the thickness of the article is at the top among the reasons that limit the MIM process for the production of rather small parts.

The sintering process for injection-molded parts does not differ significantly from that used for the press molding. However, since the “green” component has a high percentage of binder, while sintering it narrows in an important way. Primary condition is therefore that the starting mixture is perfectly smooth so as to have an identical size reduction along its three dimensions. Note that in any case very high dimensional tolerances are obtained.

The possibility of producing in mass volumes high strength complex shapes in a wide variety of different materials, makes the MIM process an excellent alternative to the molding pressure and the traditional subtractive manufacturing.

The field of application of the MIM process, after passing the initial part of the growth curve, met more and more interest on the part of the designers. The last decade has seen an annual growth rate of 10 percent that is expected to continue in the coming years, complementing the other additive technologies such as Additive Manufacturing and the HIP process.